- Measuring Instruments »

-

Work Holding Device »

- Vices

- Collet Chuck

- Collet

- CNC Sleeve

- Machine Tool Accessories

- Chucks

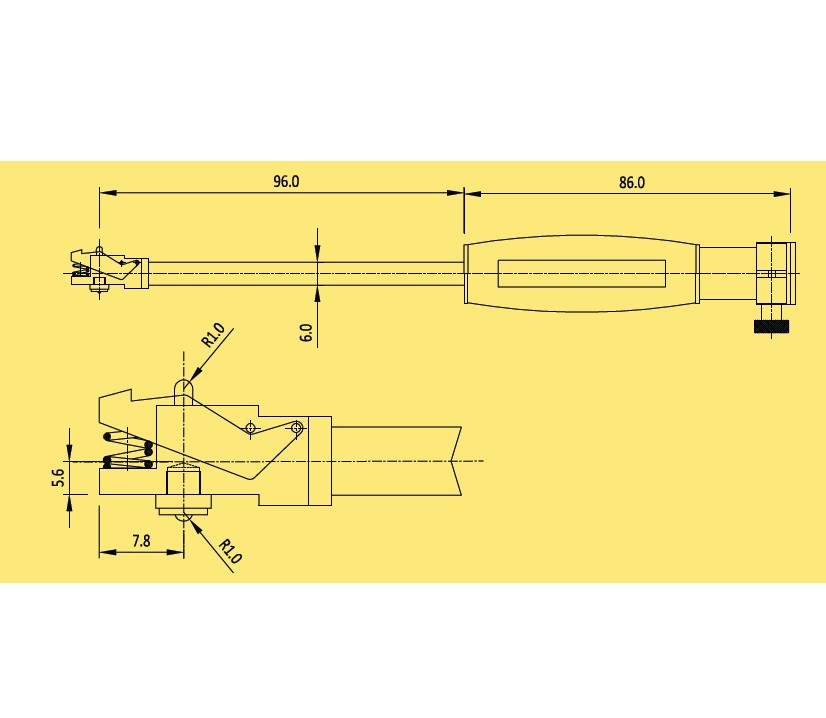

- Toogle Clamp

- Clamping Elements

- Magnet Chuck

- Torque Wrench

- Deburing Cutter

- Tool Holder

- Inserts

- Mounted Points

- Paint Spray And Air Gun

- Loctite

- Vee Block

- Lubricating Pump

- Chain Pully Block

- Tool Trolley

- Lifting Belt

- Pallet lifter And Stacker

- Die Spring

- Vibration Pads

- Machines »